Application Overview

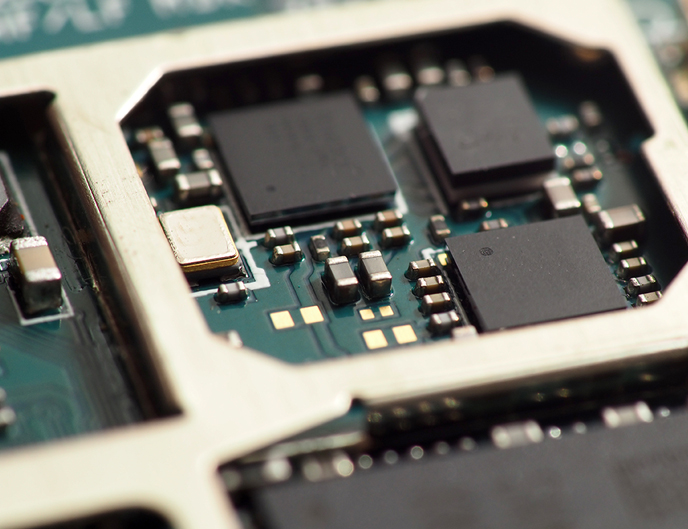

Heterogenous integration using System in Package (SiP) and advanced packaging technology enables the creation of package system solutions with lower costs, higher yields and faster time to market.

A typical SiP may contain passives components, die of different semiconductors such as Si, SiC, GaAs, GaN, Micro-Electro-Mechanical Systems (MEMS), optical components, and other packages such as Quad-Flat No-Leads (QFNs) or Chip Scale Packaging (CSP).

Various process technologies and material solutions are required to integrate the many functions into a SiP.

Interconnect Technology for SiP

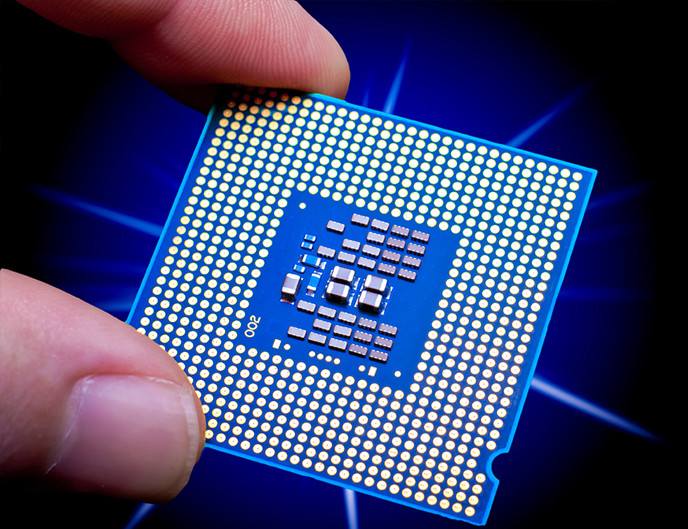

The main purpose of SiP is to combine different functionalities into one package, thereby offering system-level performance in the form factor of a single package. Key processes required for SiP:

- Die attach/stacking

- Wire bonding

- Flip chip attach

- Component/passive attach

- Encapsulation/molding

- Solder sphere attach