Encapsulation Solutions

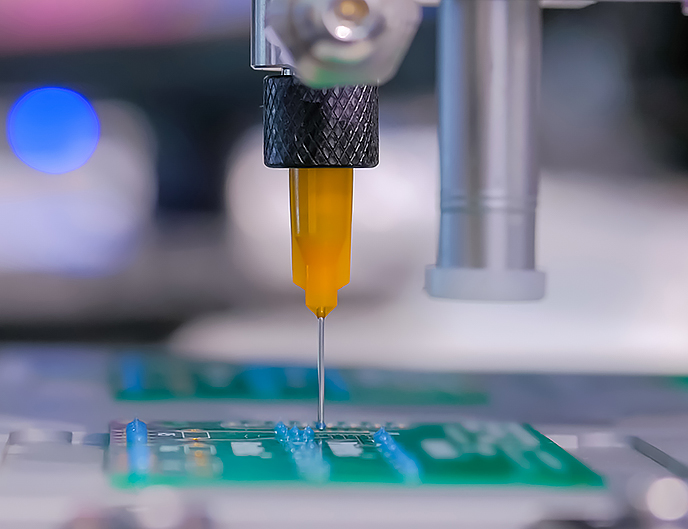

The main components of the encapsulation material are inorganic fillers such as silica, and epoxy resin which is used as a binder. Because of the advanced encapsulation materials and the automatic liquid dispensing equipment involved, it is very important to understand the encapsulation material characteristics and equipment characteristics in order to achieve the encapsulation quality and reliability.

Liquid Encapsulants Are Much More Flexible

Liquid encapsulants are much more flexible than traditional epoxy mold compounds, removing the need for expensive molding machines and molding plates. This allows greater manufacturing flexibility in production.

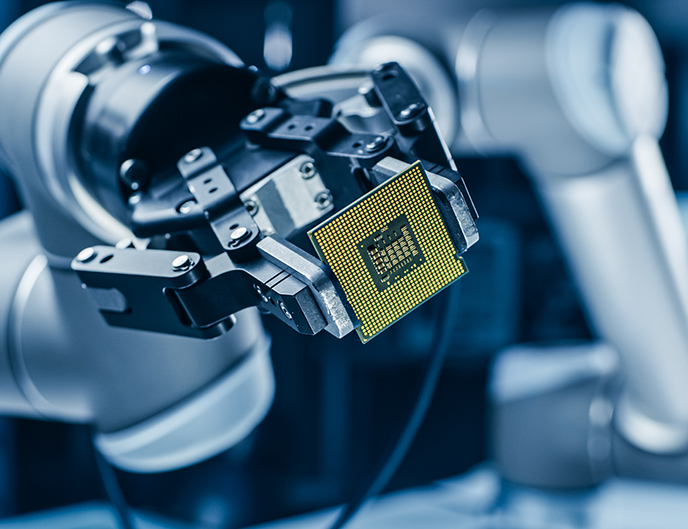

Encapsulants are primarily used to ensure environmental protection and boost the mechanical strength of wire bonded devices. They are developed to provide protection to wire bonds, leads and components.

Encapsulants deliver unmatched performance for a variety of products including transistors, system in package (SIP) devices, ASICs, and chip-on-board applications. Cycle time and costs can be reduced through the use of glob tops. These materials for chip-on- board applications are designed to cure quickly to fit easily within high-speed manufacturing operations.

Liquid encapsulants are formulated and tested in-process. They meet the most stringent JEDEC-level testing requirements and are developed to deliver outstanding performance within high temperature lead-free environments.