Leading the Electronics Industry to Reliable Microvias

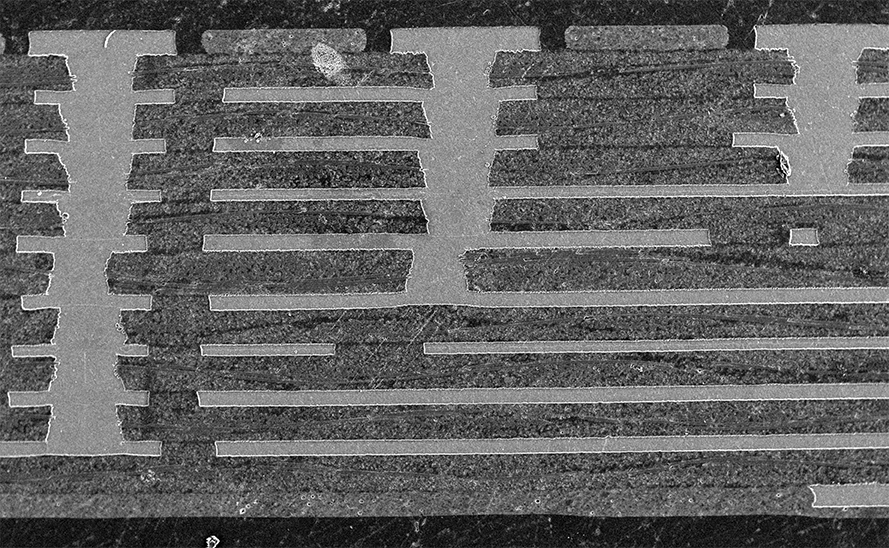

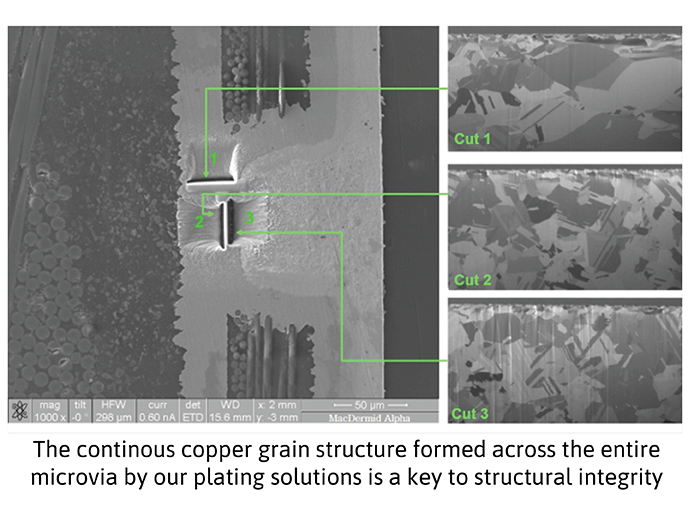

The microvia structure enabled the HDI revolution in electronics, and our solutions make it more reliable for expanded usage. The process begins with our suite of primary metallization processes including our direct metallization solutions; Blackhole®, Eclipse™, and Shadow® and our reliable electroless copper processes; M-Copper, ViaDep™ 4550, and Systek™ SAP. Once activated, our broad portfolio of via filling copper metallization processes, MacuSpec™ VF, VF-TH, AVF, and UVF series, create a reliable copper microvia structure. We specially develop these processes to work together to form a continuous copper grain structure that greatly improves mechanical performance and reliability.

To view our microvia reliability brochure, click here.

We spend countless hours studying the microvia interface and developing processing solutions. Our extensive studies with industry partners provide us with the process knowledge required to ensure a reliable microvia under a wide range of conditions, board types, and designs.

Whether you are building standard high-density interconnects for mobile boards, or designing cutting-edge IC substrates to package today’s highest performing chips, we provide next generation plating technologies that deliver highly reliable microvias.

Read our technical publication on microvia reliability here.

Solutions for Every Board Type from HDI to IC Substrates

|

Main Category |

Subcategory | General PCB/HDI | SL-PCB | IC Substrates |

|---|---|---|---|---|

|

Primary Metallization |

Direct Metallization |

|

||

|

|

Electroless Copper |

|

||

|

Electrolytic Metallization |

Via Filling Copper |

|