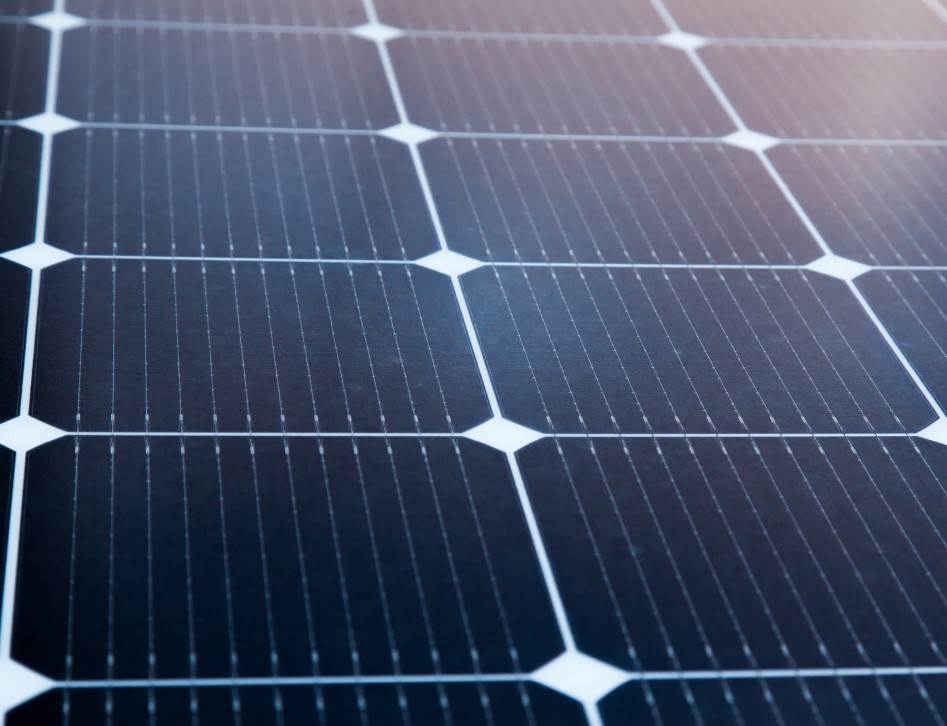

Product Overview

As the photovoltaics (PV) industry gravitates toward grid parity, chemical processing will deliver the cost, processing, and efficiency advantages needed to get us there. We are a world leader in specialty chemicals, bringing cutting-edge innovation and world-renowned technical service excellence to your facilities, anywhere, anytime. Our chemical processes enable the efficiency gains you need to win the brightest of futures.

Product Features

- Pattern Formation: Pico-second laser ablation for fingers and buss bars

-

Seed Layer Plating: Metallization options for sputtered nickel or copper

-

Conductor: Nickel and copper metal stack utilizing LIP plating technology

-

Surface Finish: Immersion Silver, Tin, OSP

As the PV industry gravitates toward grid parity, chemical processing will deliver the cost, processing, and efficiency advantages needed to get us there. We are a world leader in specialty chemicals, bringing cutting-edge innovation and world-renowned technical service excellence to your facilities, anywhere, anytime. Our chemical processes enable the efficiency gains you need to win the brightest of futures.

Photovoltaics Sales Sheet (EN)

Light Assisted Plating: A Novel Method of Electro-Deposition Technical Publication Journal Surface Finish Japan 2018 (EN)

Light Induced Electroless Plating of Silver for Efficiency Improvement and Cost Reduction of Silicon Solar Cells Technical Publication EUPVSEC 2012 (EN)

Light Induced Plating of Silicon Solar Cells Conductors Using a Novel Low-Acid, High-Speed Copper Electroplating Process Technical Publication EUPVSEC 2013 (EN)

Low Cost High Efficiency Metallization Using Ni or Cu Based Contacts for Next Generation Industrial Solar Cells Technical Publication SNEC 2014 (EN)

Low Cost Metallization Based on Ni/Cu Plating Enabling High Efficiency Industrial Solar Cells Technical Publication EUPV Solar Energy 2014 (EN)

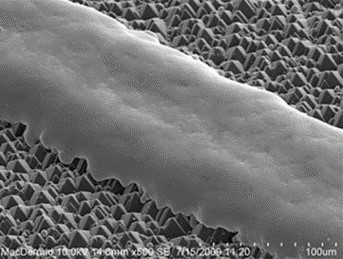

Pilot Production of High Efficient Metal Catalyzed Textured Diamond Wire Sawed mc-Si Solar Cells Combined with Nickel-Copper Plated Front Contact Processing Technical Publication EU PVSEC 2017 (EN)

Reliable Contact Formation for Industrial Solar Cells by Laser Ablation and Ni-Cu Plating Technical Publication EU PVSEC 2014 (EN)

Plated Metal Conductors

MacDermid Enthone provides numerous options for the deposition of metals to form the conductor grids on solar cells. These options include electrolytic, electroless, and immersion deposition options for metals such as nickel, copper, silver, and tin.

Solderable Finishes

Your cell's solderable finish represents your connection to the outside world. Each of the cell's electrons needs to be transmitted through the conductor to the module strings without loss while achieving maximum consistency. Our metal finishing options provide long-term prevention of conductor oxides allowing for easy soldering with any flux system and solder alloy. Each product allows superior functionality for front or rear side plating and can also be used with conductive paste contacts used in shingling applications. Plated metal conductors significantly outperform sintered paste for conductivity, allowing finger-width reductions to 20 microns or less. Immersion silver and immersion tin surface finish options also provide superior solderability for solder tabbing as well as reduced contact resistance for modules utilizing shingling technologies.

Helios® Electrolytic Nickel

Light-induced plating (LIP) electrolytic nickel is used as the barrier layer between the silicon and the plated copper layer. The nickel layer is typically around 1 um thick and must exhibit low stress and a dense, uniform deposit.

Helios Electrolytic Copper

Full-build, high-purity, low-stress copper for fast deposition of up to 50 microns thickness for the ultimate finger and busbar conductivity. Easily finished with silver or tin. Helios Electrolytic Copper is available in light-induced formulation as well.

Helios Electrolytic Silver

Cyanide-free. The highest conductivity metal deposit for use as a full-build conductor, plating on silver paste, or the final coating on copper or nickel deposits. Helios Electrolytic Silver can be applied utilizing LIP or in fully electrolytic mode.

Helios Immersion Silver

Silver protects the conductors for soldering with the most functional and cost-competitive surface finish available. Helios Immersion Silver applies a deposit of pure silver in high-speed batch or conveyorized equipment without the need for electrolytic contact.

Helios Immersion Tin

For PV applications that specify tin as the final solderable finish, the industry chooses Helios Immersion Tin. The production-proven chemistry can be used in various plating tool types with excellent solderability and resistance to environmental contamination.

Solder Interconnect Technology

Our Alpha brand solder interconnect technology helps optimize your PV assembly process. Our global experts can guide you through choosing the right set of materials for high throughput, high-yield production, and high efficiency, high reliability solar modules. Use Alpha products for: liquid tabbing & stringing fluxes, solder wire, solder paste, and solder preforms.