Product Overview

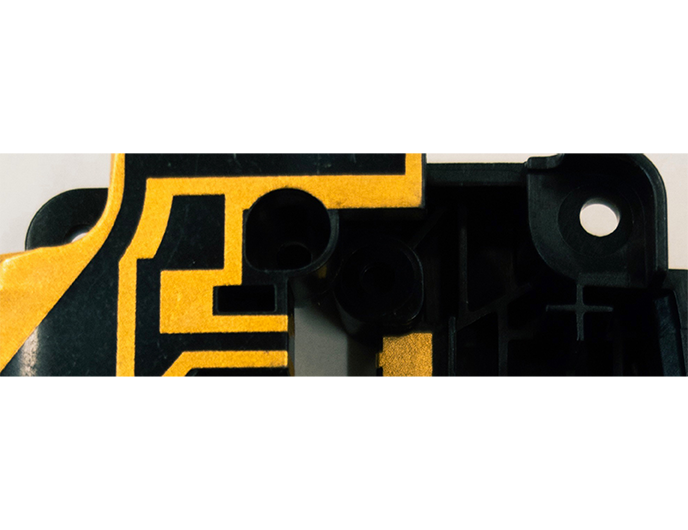

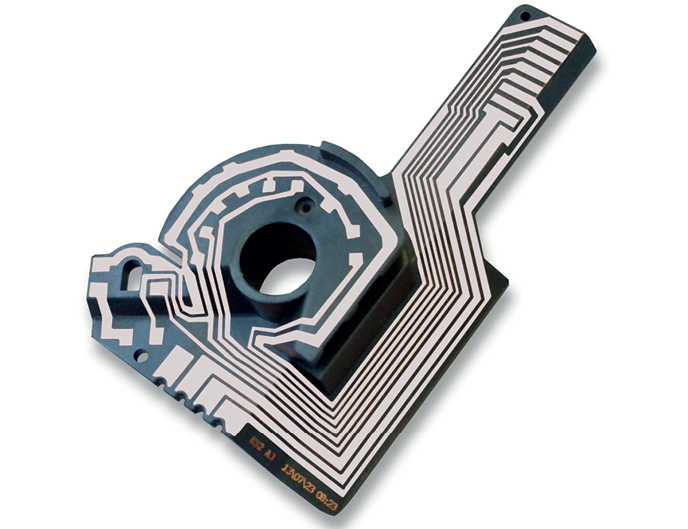

MacDermid Enthone's molded interconnect devices (MID) plating solutions are specifically designed and optimized to deliver precise selectivity, high yields, and ease-of-use for laser direct structured, catalytic ink, and double-shot molded interconnect devices. Delivering consistent selectivity on a wide variety of materials and catalysts, our copper, nickel, gold, and silver plating solutions enable more complex and efficient designs on the most desirable and low cost molding composites. Simple and controllable processes result in steady plating rates coupled with long and predictable bath performance.

MID applications are rapidly expanding into new and exciting areas in electronics applications. Once a mainstay in mobile devices, increasing opportunities are now spreading within the medical, automotive, and lighting industries. As these opportunities expand, new materials have been considered to address physical properties and costs related to the application.

Product Features

- Unmatched selectivity on laser direct structured materials

- Highest yields on all current and emerging plastics

- Stable, long-lasting, easy-to-use chemical processes

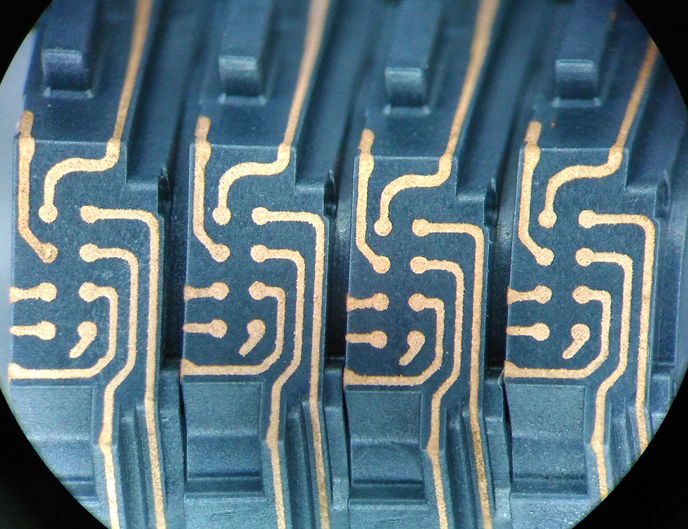

- High tech applications in fine pitch plating and wire bonding

Molded Interconnect Devices (MID) are rapidly expanding into new and exciting areas in electronics applications.

MID Selective Metallization Sales Sheet (EN)

High Elongation Electroless Copper Technical Publication SMTAI 2018 (EN)

MID Technologies Dual Presentation 2015 (EN/SC)

MID Technologies Presentation 2015 (EN)

Innovative MID Plating Solutions Presentation (EN)

Fine Line Plating Enhancer

LDS Selectcoat 100 FL: As the applications for molded interconnect devices have expanded from simple, large antennae constructions to advanced electronic devices, conductor line sizes have become an issue due to laser debris deflection, leading to extraneous bridging during electroless deposition. LDS Selectcoat 100 FL completely solves this issue by acting as a sacrificial layer which can be removed from the part after laser direct structuring, leaving behind a pristine surface between LDS traces, allowing for compact design with finer geometries.

Copper Plating

MID Copper 100: This industry-leading electroless copper chemistry enables manufacturers and designers of MID to selectively metallize plastics activated through laser and 2x molding methods. Our MID Copper provides unmatched yields and high plating rates from a chemical process with exceptional stability.

Nickel Plating

ENPLATE® LDS NI 200: A highly stable, electroless nickel process that deposits a smooth, semi bright mid-phosphorous nickel coating on copper plated LDS substrates.

MID LT Nickel 100: Low, medium, and high phosphorus nickel systems, all with exceptional stability. Each process will provide best in thickness uniformity combined with corrosion and salt spray resistance.

Final Finish

Delivering consistent selectivity on a wide variety of materials and catalysts, our final finish solutions enable more complex designs on low-cost molding composites. These simple-to-control processes offer steady plating rates and predictable bath performance.

ENPLATE LDS AG 600: The ENPLATE LDS AG 600 provides a complete and compelling alternative to nickel/gold as a final finish. Designers and manufacturers can realize significant cost reduction through gold elimination, elimination of nickel, and exceptional electrical performance. Our unique technology will assure environmental/corrosion resistance meets end-use requirements.

ENPLATE LDS AU 301: Designed to operate at low metal concentrations, this MID specific process will allow manufacturers to lower operating costs. Deposits exhibit exceptional solderability, contact resistance, and color uniformity.