Product Overview

Over the past 30 years, we delivered cutting-edge electroless nickel chemistry to the memory disk industry. We strive to meet and exceed the rigorous product requirements specified by disk manufacturers. With our many years of experience, we offer a total line of pre-treatment and electroless nickel chemistries. By providing a full product line, our customers benefit from an optimized process that produces memory disks of the highest quality. All of our electroless nickel and pre-treatment chemistries are RoHS compliant.

Product Features

- Total line of pre-treatment and electroless nickel chemistries

- Optimized processes for the highest quality memory disks

- All of the pre-treatment and electroless nickel processes are RoHS compliant

Over the past 30 years, we delivered cutting-edge electroless nickel chemistry to the memory disk industry. We have strived to meet and exceed the rigorous product requirements desired by disk manufacturers.

Enklad Pretreatment Sales Sheet (EN)

Enklad Cleaner-Etch 100

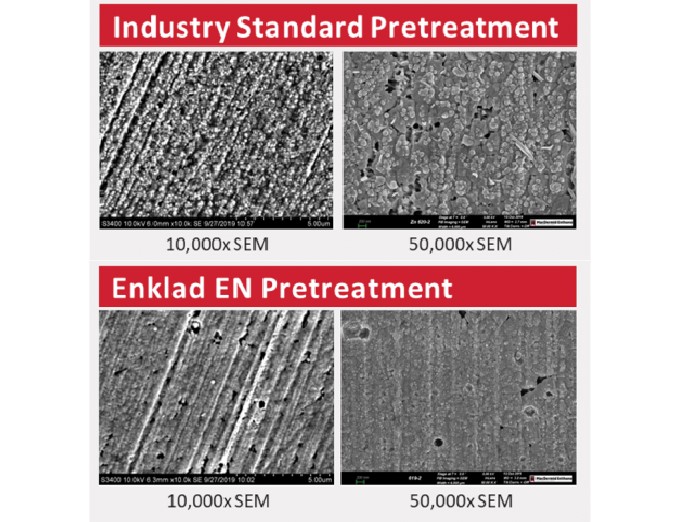

The Enklad Cleaner-Etch 100 incorporates chemistry that combines both substrate cleaning and etching in one step. When comparing to the industry standard equivalent, it produces less pitting in the aluminum substrate with more uniform and mild etching, while also preparing the disk surface for the zincate. The low foaming formulation allows for ease of production and its higher cloud point ensures a wide operating window.

Enklad Zincate 100/100R

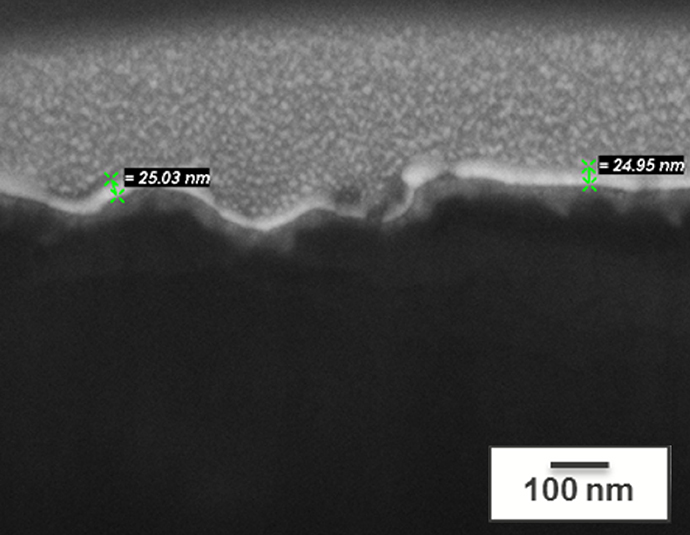

Conventional zincate solutions are ineffective in meeting the demands of increased production volume, as well as the variability of aluminum substrates currently plated. The Enklad Zincate 100/100R overcomes issues associated with these different aluminum substrates. It deposits a thinner, more uniform zincate coating with exceptional adhesion to the aluminum surface in two steps. The second step has the benefit of lower risk of drag-out contamination of the subsequent electroless nickel bath, thus improving process control.

Electroless Nickel Products

Our electroless nickel chemistries for memory disk produce high percentages of phosphorous deposits with superior corrosion resistance and excellent thermal magnetic stability. All of our electroless nickel products yield deposits with low PDI and other micro-defect,s as well as offer the unique ability to operate at high metal turnover which significantly reduces customer waste streams.