Product Overview

Adhesion between the innerlayer copper circuits and the resin is critical for long term reliability of the printed circuit or IC substrate. The MacDermid Enthone brand has a portfolio of different copper surface treatments to meet the needs of any application. To compliment the expanding use of low-profile copper foils for high frequency applications, we also provide surface treatment options that are designed specifically for high speed/low-loss applications. MacDermid Enthone’s products are specifically engineered to provide robust reliability across a wide range of resin systems and copper foil types, and can meet the system requirements for any application type.

Product Features

- High reliability innerlayer bonding on a wide variety of materials

- Prepares copper surfaces for optimum efficiency

- Compatible with a full range of resins

- Complete offering of surface treatment systems

- Signal integrity/low loss for high speed applications

Adhesion of copper circuitry to substrate materials is important for circuit integrity during layer build-up and assembly conditions. We offer a wide portfolio of chemical treatments for the copper surfaces that make up the circuitry of printed circuit boards and IC substrates.

MultiBond MP Sales Sheet (EN)

M-Speed HF Sales Sheet (EN)

M-Speed HF Sales Sheet (SC)

Controlling Moisture during Inner layer Processing Technical Publication APEX 2013 (EN)

Optimizing Morphology of Plated Copper Sub Assemblies through Oxide Alternative Process Technical Publication ECWC 2013 (EN)

Reliability Testing of Oxides and Oxide Alternatives for Inner Layer Bonding Technical Publication APEX 2013 (EN)

Systek IC Substrate Brochure (EN)

Innerlayer Bonding

We are a leader in the development of high reliability bonding conversion coatings for multilayer printed circuit boards. MacDermid Enthone consistently innovates new innerlayer bonding coatings to meet the requirements of new resin systems and application requirements.

MultiBond™ MP

MultiBond MP is a uniquely formulated copper conversion coating for multilayer printed circuit boards, combining micro-roughening with an embedded organic coating. MultiBond MP is used in high-throughput automated horizontal conveyorized systems for fast, consistent processing of thin core innerlayers. It is the ideal bonding process for controlled impedance innerlayers on advanced resin systems. With up to an 80% reduction in concentrated copper waste and low-etch depth, MultiBond MP is the industry’s choice for innerlayer manufacturing.

OmniBond Plus+

OmniBond Plus+ is a specially formulated oxide that provides optimum innerlayer adhesion in multilayer printed circuit boards. It produces a fine grained copper oxide which gives excellent results on epoxy, multifunctional, and polyimide boards. The OmniBond Plus+ process is the only production-proven oxide dissolution system offering pink ring elimination and lower incidence of high-resistance shorts than DMAB reduced oxide. Both processes offer multi-resin compatibility for optimum process flexibility.

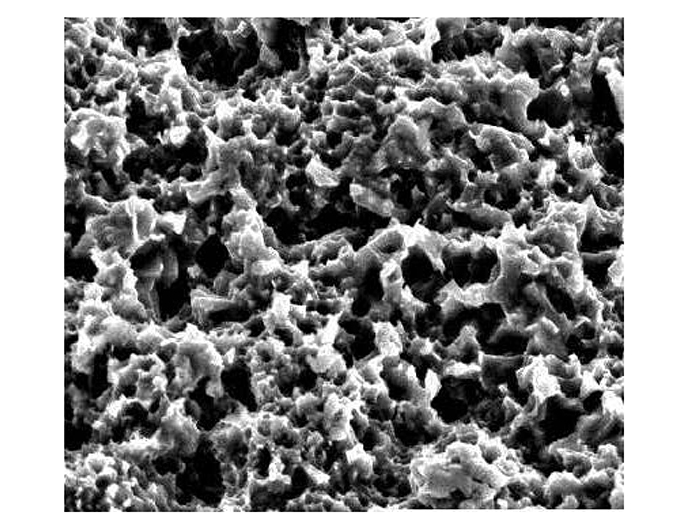

AlphaPrep®

Our AlphaPrep alternative oxide processes are used worldwide. With offerings that provide moderate surface roughness from 35 to 70 µ”, and are capable of high copper loading before bath replacement, AlphaPrep technology provides roughness on most material and copper types.

COBRA BOND®

COBRA BOND alternative oxide has more than ten years of proven performance, and is well suited to many types of board material and copper surfaces. A roughness range of 35 to 50 µ”, and a very high copper bath loading capability, makes COBRA BOND the roughness process of choice for shops needing lower maintenance.

M-Speed HF

M-Speed HF is a complete process that improves signal integrity for high-speed innerlayers. The uniquely formulated M-Speed HF process is developed from our decades of leadership with innerlayer technologies. The low-etch oxide alternative coating provides low surface profiles and reliable adhesion for high frequency applications. M-Speed HF creates an exceptional surface topography on all three exposed sides of the copper trance to ensure electrical properties meet the needs of high frequency designs. The superior adhesion and maximum thermal resistance afforded by M-Speed HF is achievable, despite lower peak to valley roughness on the copper surface, making it superior for fine traces. The M-Speed HF system achieves this industry-leading performance in as few as three process steps. This surface provides unparalleled innerlayer bonding to a wide variety of resin systems and dielectric films.

Copper Surface Preparation

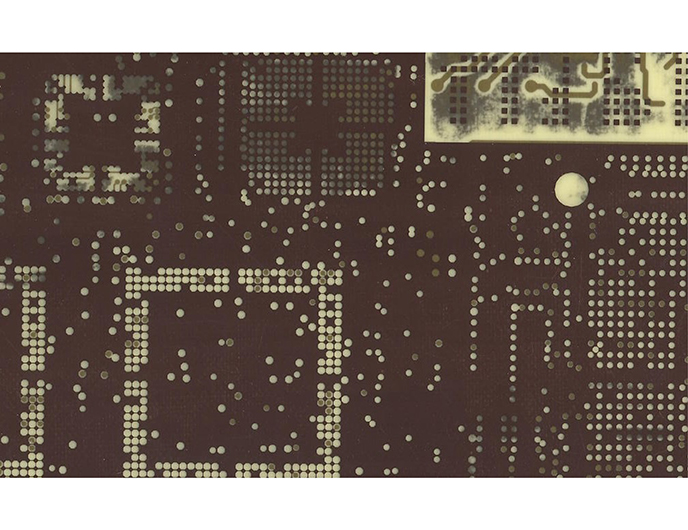

MultiBond™ 500 is an innovative low-etch alternative oxide for laser direct drilling. Due to its improved topography, color, and lower-etch depth, the process enables improvements in laser direct drilling of vias while providing optimized topography for the most demanding adhesion requirements. The process provides a highly uniform dark colored alternative oxide coating for lasering. From start to finish, MultiBond 500 removes less than 1 micron of copper from the surface.

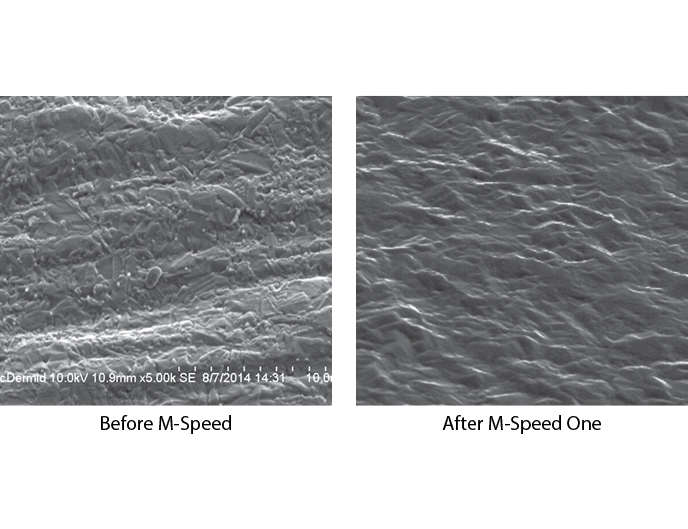

Dry Film Adhesion

M-Speed One is a peroxide-/sulfuric-based micro-etch cleaner for copper surfaces. It removes organic, inorganic soils, and oxides from the surface, etches copper at a reliable and steady rate, and inhibits corrosion of the copper surface, all in one process step. When used prior to dry film lamination, M-Speed One creates ideal surface topography and inhibits oxidation for improved adhesion.