Product Overview

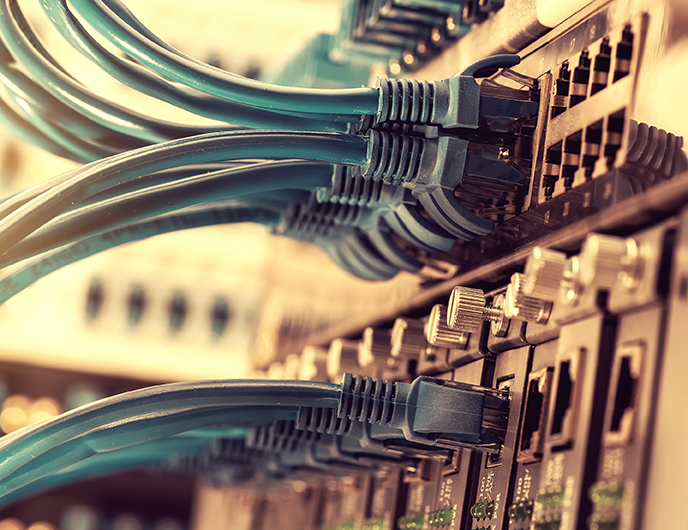

Whether you need durability, long lasting corrosion resistance, or functional final finishes, we have a wide range of chemical processes for finishing connectors and interconnects.

The MacDermid Enthone brand of connector finishing technology meets the demands for increasingly complex shapes, finer features, and greater reliability. Through reduced consumption, greater metal selectivity, and increased productivity, every process is designed with the lowest cost of ownership in mind.

Product Features

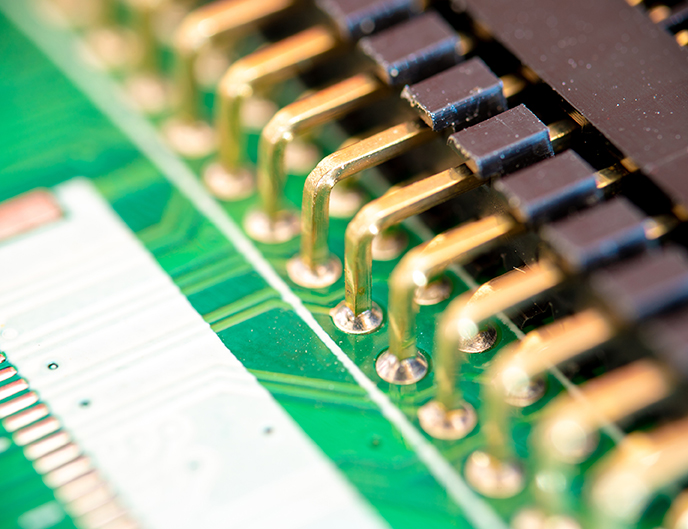

- Pre-treatments: specially formulated cleaners and activators for a wide range of substrate metals.

- Base metals: matte and bright coppers, nickels, and nickel alloys that provide a robust foundation for long-term adhesion and reliability.

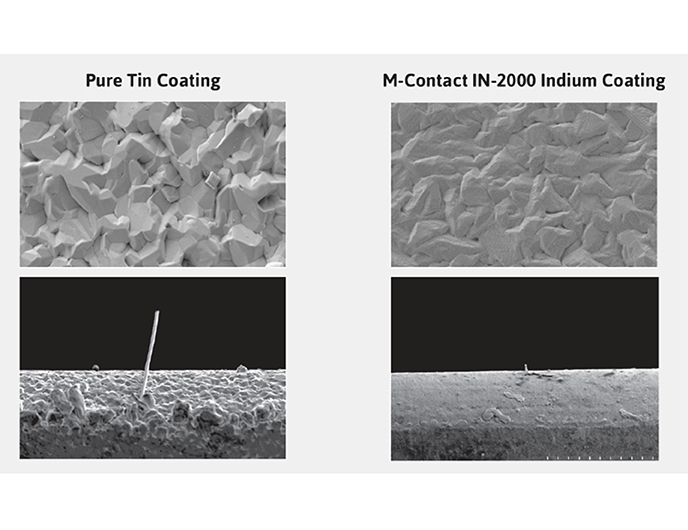

- Tin: bright and matte deposits that are highly solderable and have excellent whisker resistance.

Whether you need durability, long lasting corrosion resistance, or functional final finishes, we have a wide range of chemical processes for finishing connectors and interconnects.

Pre-Treatment

Cleaner and Degreasers

Alkaline electrocleaner for steel and copper

Activators

Fluoride containing acid salt for activation of copper, copper alloys, and steel

Copper

Bright, Matte

High speed plating for mid to high current densities, available in either sulfuric acid or MSA solutions.

Strike

Cyanide-based copper strike.

Nickel/Nickel Alloys

Nickel-Tungsten Alloy

Sulfamate based nickel-tungsten (35-45 wt% W) deposit for improved wear and corrosion resistance. High speed / wide plating window allows tight control of alloy composition.

Nickel-Phosphorus Alloy

Sulfamate based nickel-phosphorous (3-12% wt% P) deposit for improved corrosion resistance and non-magnetic properties. High speed / wide plating window allows tight control of alloy composition.

Semi-Bright Matte Pure Nickel

Deposits a semi-bright, slightly tensile stressed, and ductile layer. Ideal undercoat for precious and non-precious metal deposits.

Palladium

Pure

Bright, ductile deposit for use in reel to reel or rack and barrel applications.

Palladium Alloy

“HS” - High Speed, “LS” - Low Speed, and reduced consumption options. Bright, ductile deposits, exceptional contact stability and wear resistance.

Tin

Matte (MSA)

High speed, high efficiency, low foam electrolytes for deposition of pure tin over a wide current density range. Low stress deposits for whisker mitigation.

High efficiency, low speed, low foam electrolytes designed for rack and barrel deposition of pure tin. Light color and fine grain with a matte, uniform appearance.

Bright (MSA)

High speed, reel to reel or rack and barrel plating solutions with wide current density ranges. High brightness, low stress deposit with low carbon occlusion.

Indium

Acid

High speed, high efficiency, MSA based electrolyte. Long bath life, low maintenance, and simple bath control. Uniform plating at a wide current density range.

Gold

Cobalt Alloy

Bright yellow deposit, low porosity, and high purity. Stable process with high efficiency and speed at high current densities; minimal over-plate at low current densities.

Nickel Alloy

Selective, high-speed, mirror-bright deposits. Consistent and uniform deposits over a wide range of current densities. Suitable for both reel to reel or rack and barrel applications.

Cobalt or Nickel

General purpose bath for both nickel and cobalt hardened applications.

Gold Strike

Mildly acidic gold strike for enhanced adhesion of subsequent plated deposits.

Silver

Low Speed

Low speed silver plating process for rack and barrel applications.

High Speed

High speed silver plating for reel to reel plating with inert anodes.

Post-Treatment

Silver Post Treatments

Electrolytic, high-speed, water-based organic solution.

Electrolytic, high speed, Pd base, high heat resistance.

Immersion solution, solvent-based organic solution.

Gold Post Treatments

Electrolytic, high-speed, water-based organic solution.