Electronics Manufacturing Processes for High-Speed Devices

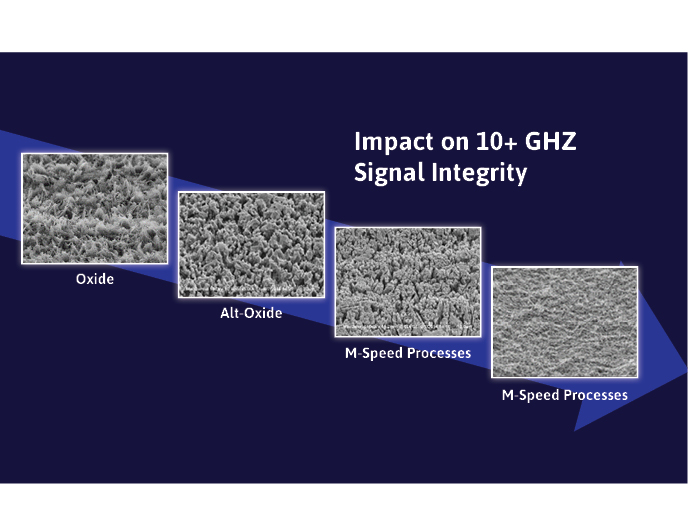

With the integration of many subsystems in today’s advanced electronics, high speed signal challenges are becoming increasingly common to electronics manufacturing. We offer a suite of solutions that can help printed circuit board (PCB) fabricators and original equipment manufacturers (OEMs) build and design circuit carriers that transmit signals with lower loss and improved electrical properties than previously possible with standard manufacturing technologies. Our M-Speed, MultiPrep, and CircuEtch technologies are at the forefront of technological achievement for the precise tuning of copper surfaces for excellent bonding, topography, and material adhesion.

M-Speed

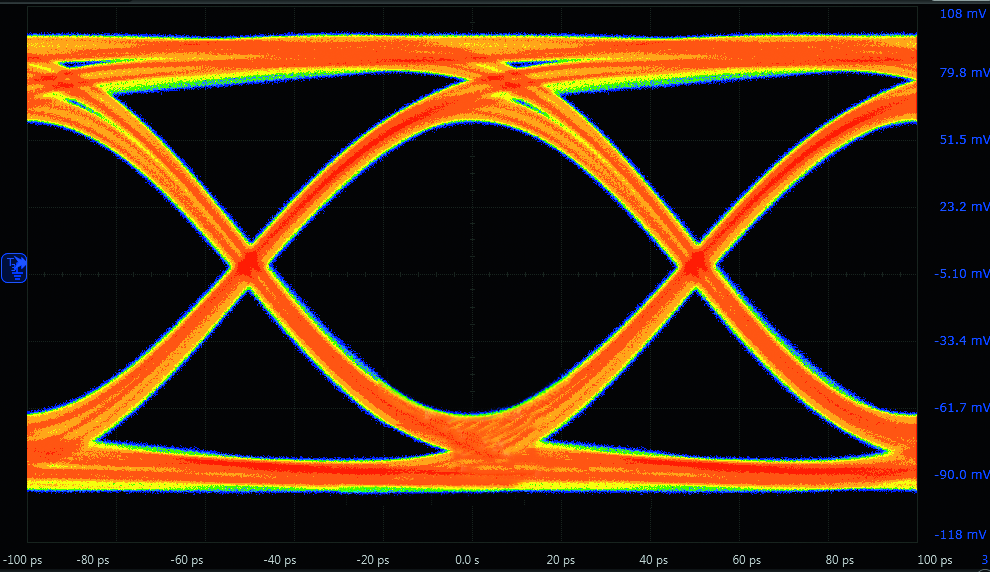

M-Speed is our complete copper surface treatment process for fabrication of printed circuit boards in applications demanding the lowest signal loss. This uniquely formulated process, developed from our decades of leadership with innerlayer technologies, provides low surface profiles and reliable adhesion for high frequency applications. Our M-Speed One is an innerlayer dry film adhesion promotion system for boards that have high frequency requirements. Our revolutionary low-etch oxide M-Speed HF provides low profile surface topography to ensure maximum signal speeds, meeting the needs of controlled impedance and perfect signal integrity. The superior adhesion and maximum thermal resistance afforded by M-Speed HF is achievable, despite lower surface topography and lower peak to valley roughness on the copper surface, making it superior for fine traces.

The M-Speed HF system achieves this industry-leading performance in as few as three process steps. The process combines a holistic approach for dry film adhesion and innerlayer bonding including clean, prep, and oxide alternative post treatment. This surface allows excellent adhesion to a wide variety of photoresists as well as unparalleled innerlayer bonding strength. M-Speed HF provides flexibility of processing using environmentally friendly chemistry.

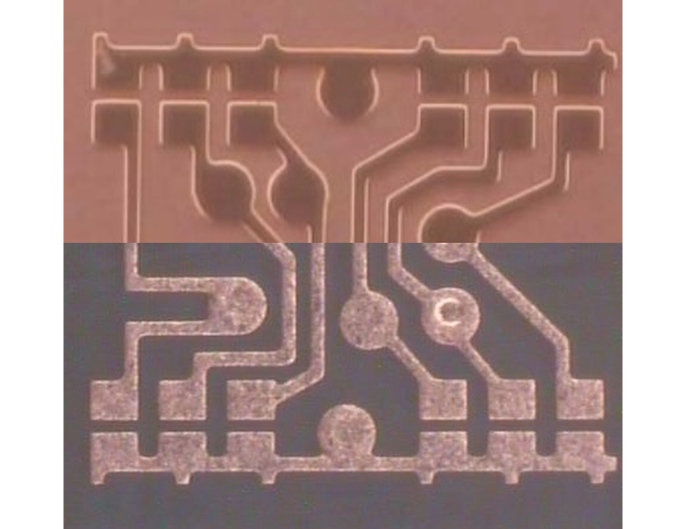

CircuEtch

The CircuEtch series of processes are high performance flash etches that can be utilized for innerlayer processing of mSAP and SAP manufacturing of high-density interconnects. CircuEtch 100 is a controlled high-speed copper reduction process that can remove up to 8 microns of copper per minute, while providing a polished etch surface that has reduced roughness compared to the starting copper. CircuEtch 300 is high-speed anisotropic final etch for SAP and mSAP that can be used to form advanced HDI circuitry on package substrates and substrate-like PCBs with excellent precision and surface topography. The process provides vertical trace sidewalls without undercut and etches thin copper foils and electroless copper seed layers with precision. CircuEtch baths have stable and easy-to-maintain process chemistry, enabling a high degree of manufacturing precision for high quality.