ALPHA SF828-MBB is a low solids content, alcohol based, zero-rosin, no-clean liquid flux for most standard and multi-busbar PV interconnections. ALPHA SF828-MBB contains a unique blend of ingredients that overcome the smaller surface area of wire ≤0.4mm used in ever evolving multi-busbar technology to achieve excellent interconnection.

ALPHA SF828-MBB enables a wide process window and requires minimal heating before fluxing. It delivers excellent peel force that results in long term reliability of the solder joints.

- Fast wetting with minimal or no heating prior to wire ribbon dipping for higher process efficiency

- Reduced placement slipping for improved production yields

- Less residue to support higher power transfer efficiencies and less equipment maintenance

- Superb adhesion and no yellowing bubbling across different EVA laminations

- High peel strength and long-term reliability

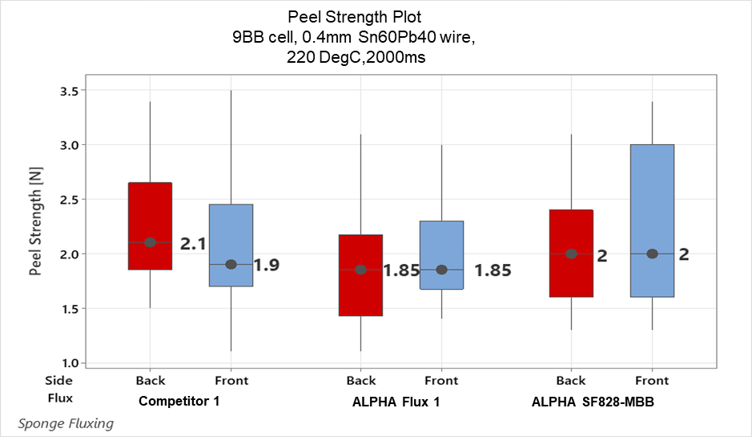

ALPHA SF828-MBB Delivers High Peel Strength

The high peel strength provided by ALPHA SF828-MBB ensures long term reliability of the solder joints for long module life, as well as good soldering yields and satisfactory ribbon-cell interconnection.

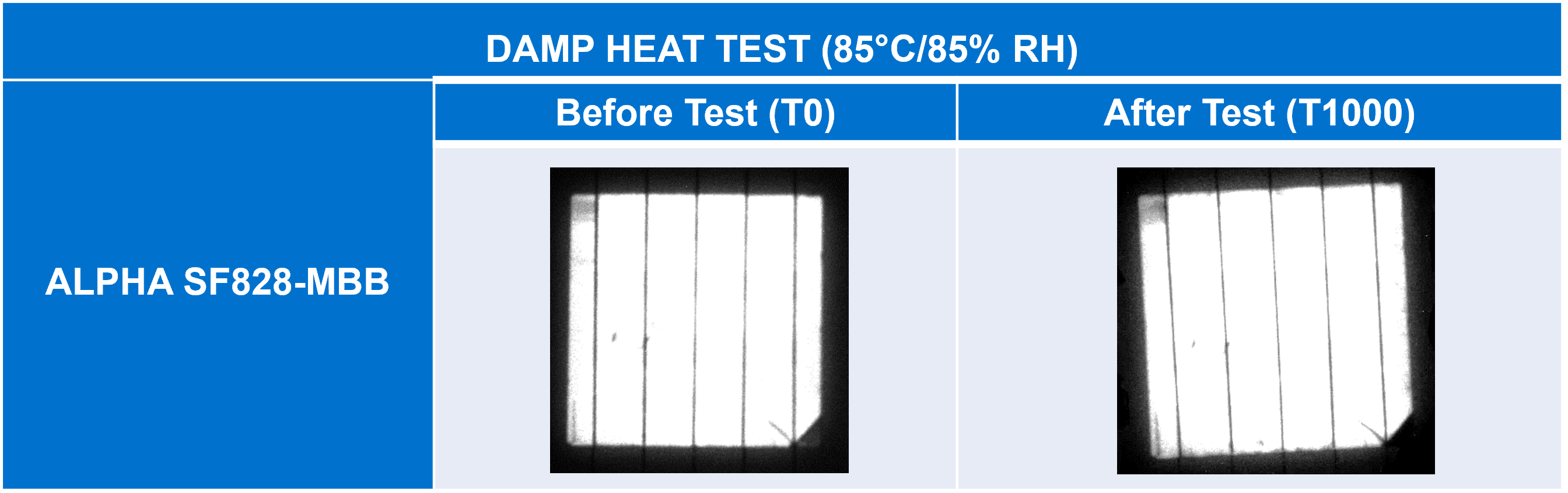

Damp Heat Test

ALPHA SF828-MBB electroluminescence analysis showed no color degradation and smudging of the flux layer observed. The soldering and bonds remain intact.