Product Overview

MacDermid Alpha Electronics Solutions offers a variety of through hole metallization processes from our MacDermid Enthone brand to accommodate any challenge. Our high throw direct current offerings include the HiSpec 2, MacuSpec™ HT series, and CUPROSTAR® ST-2000 processes. Our pulse plating offerings include the MacuSpec PPR, MPR, and PC 600 series processes. Our processes are production proven and offer solutions for the metallization of the most advanced high aspect ratio boards.

Product Features

- High throw DC portfolio enables pulse-like plating in DC equipment

- MacuSpec HT series DC baths offer throwing power of greater than 80% at 30 ASF

- Pulse plating portfolio offers superior microdistribution with wide operating windows

- Industry recognized pulse baths including MacuSpec PPR, MPR, and PC 600

Our high throw direct current offerings include the HiSpec 2, MacuSpec HT series, and ST-2000 processes. Our pulse plating offerings include the MacuSpec PPR, MPR, and PC 600 series processes. Our processes are production proven and offer solutions for the metallization of the most advanced high aspect ratio boards.

MacuSpec HT 300 Sales Sheet (EN)

MacuSpec HT 360 Sales Sheet (EN)

MacuSpec PPR 200 Sales Sheet (EN)

PC 600 Sales Sheet (EN)

PC 600 Sales Sheet (SC)

High Throw DC Acid Copper Formulation for Vertical Continuous Electroplating Processes Technical Publication APEX 2017 (EN)

High-Throw DC Acid Copper Formulation for Vertical Continuous Electroplating Processes Technical Publication PCB007 2017 (SC)

High-Throw DC Acid Copper Formulation for Vertical Continuous Electroplating Processes Technical Publication PCB007 (EN)

Innovative Acid Copper Process For Simultaneously Filling Vias And Plating Through Holes Technical Publication HKPCA 2017 (EN)

Innovative Acid Copper Process For Simultaneously Filling Vias And Plating Through Holes Technical Publication SMTAI 2018 (EN)

Periodic Pulse Plating of Mid-Aspect Ratio Printed Circuit Boards for Enhanced Productivity Technical Publication SMTAI 2019 (EN)

The Effects of Board Design on Electroplated Copper Filled Thermal Vias for Heat Management Technical Publication SMTA SE Asia 2017 (EN)

Via Fill and Through Hole Plating Process with Enhanced TH Microdistribution Technical Publication APEX 2018 (EN)

High Throw Direct Current

Our portfolio of High Throw DC Acid Copper plating solutions meet the needs of any application requiring DC plating. The high throwing power extends the need to upgrade to pulse plating for many designs. All baths are compatible with our industry leading portfolio of primary metallization processes for enhanced performance.

MacuSpec HT 200

MacuSpec HT 200 is specifically formulated to provide high microdistribution at higher current densities for increased throughput making it an excellent choice for systems such as continuous vertical platers. The MacuSpec HT 200 acid copper system deposits a bright, smooth, ductile copper deposit with a current density range of 5 to 30 ASF with the capabilities of plating through holes with aspect ratios up to 10:1. The mechanical properties of the plated deposit exceed IPC specifications across the entire current density range.

MacuSpec HT 300

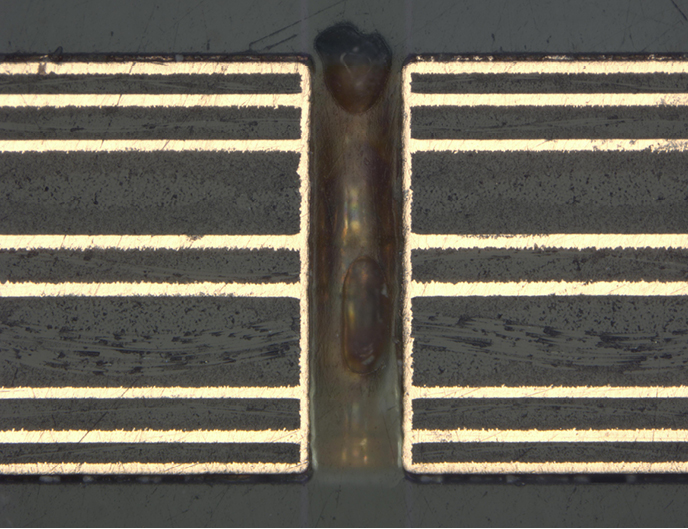

MacuSpec HT 300 is a high throw DC acid copper plating process providing pulse plating-like performance on thicker boards in standard DC copper plating equipment. This process produces deposits with exceptional brightness, ductility and uniformity in through holes with aspect ratios up to 15:1 aspect, allowing fabricators to produce higher technology boards without upgrading their rectification to pulse. The MacuSpec HT 300 is an excellent choice for through hole plating, conformal blind via plating, and pattern plating applications.

The MacuSpec HT 300 deposit exceeds IPC Class 3A tensile strength and elongation requirements and passes all thermal reliability testing ensuring dependable device performance. MacuSpec HT 300 is analyzable by CVS and common analytical tools for excellent operational control, bath life, and improved product quality.

MacuSpec HT 360

MacuSpec HT 360 is a state-of-the-art direct current acid copper plating process that provides greater throwing power at current densities up to 30 ASF in through holes with aspect ratios up to 15:1. The increased throwing power and higher current density provides greater throughput while minimizing excess surface copper extending the capabilities of DC plating.

The MacuSpec HT 360 deposits exceed IPC Class 3A tensile strength and elongation requirements and passes all thermal reliability testing ensuring dependable device performance. MacuSpec HT 360 is analyzable by CVS and common analytical tools for excellent operational control, bath life, and improved product quality.

HiSpec 2

HiSpec2 is a unique acid copper plating system designed primarily for high aspect ratio PWB production. The highly stable, low organic additive system combined with a high free acid to copper ratio electrolyte, provides increased throwing power compared to conventional acid copper processes. HiSpec2 produces semi-bright, fine grained, ductile copper deposits over a current density range of 1 - 30 ASF with unparalleled uniformity of deposit properties.

CUPROSTAR ST-2000

CUPROSTAR ST-2000 is a direct current acid copper plating process that provides greater throwing power at current densities up to 30 ASF in through holes with aspect ratios up to 15:1. The increased throwing power and higher current density provides greater throughput while minimizing excess surface copper extending the capabilities of DC plating. CUPROSTAR ST-2000 deposits exceed IPC Class 3A tensile strength and elongation requirements and passes all thermal reliability testing ensuring dependable device performance.

Pulse Plating

For circuit board manufacturing with very high layer counts and high aspect ratio through holes, our portfolio of Periodic Pulse Reverse acid copper plating processes provides exceptional reliability for thick, high technology boards, while also providing the excellent process throughput expected of pulse plating.

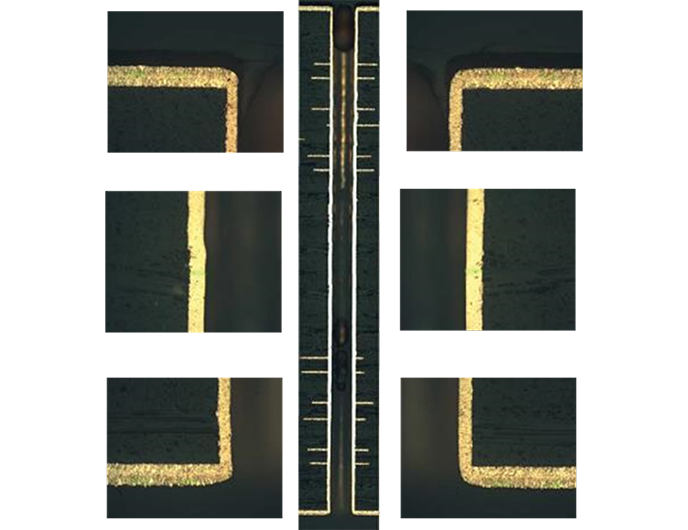

MacuSpec PPR 100 and 200

MacuSpec PPR 100 and 200 are industry leading pulse plating processes trusted by fabricators worldwide who demand precise thickness uniformity and overall productivity unattainable by conventional acid copper plating. These processes are designed for the metallization of high technology panels with through hole aspect ratios approaching 30:1.

The PPR 100 and 200 processes provide excellent thickness uniformity, reliable thermal cycle performance, and superior throwing power into both through holes and blind vias.

MacuSpec MPR 100

MacuSpec MPR 100 is a pulse plating process designed as a lower cost option for mid aspect ratio technologies with aspect ratios up to 15:1. Combined with lower cost, basic pulse rectification, the MacuSpec MPR 100 is a cost effective alternative to high throwing power DC plating providing higher throwing power, reduced surface copper, and increased plating rates. The result is increased throughput, reduced copper anode consumption, and reduced copper etching needs.

PC 600

PC 600 is an industry leading pulse plating processes trusted by fabricators worldwide who demand precise thickness uniformity and overall productivity unattainable by conventional acid copper plating. These processes are designed for the metallization of high technology panels with through hole aspect ratios approaching 30:1.

The PC 600 process provides excellent thickness uniformity, reliable thermal cycle performance, and superior throwing power into both through holes and blind vias.