Product Overview

Shadow is an advanced direct metallization for HDI and flex type constructions which allows for plating of complex designs in a simple and easy to control process. Shadow makes through-holes and blind vias conductive for subsequent copper electroplating. 35+ years of patented technology, over 300 lines and more than 1 billion boards produced: Shadow delivers what matters.

Product Features

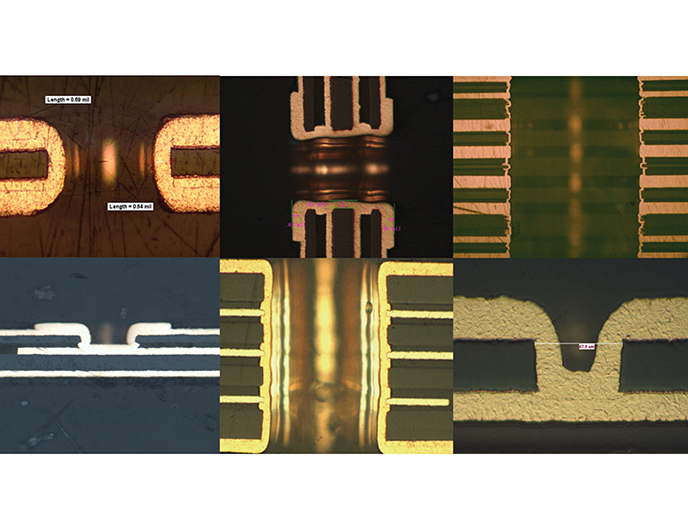

- Lowest particle size for fine feature performance

- Unsurpassed reliability verified with IST, OM, Via-Pull, HATS and Thermal Cycling

- Copper via fill plating with no flash plate, improving production flow and cost models

- Simple, easy to control, four step process enables higher throughput

- High copper-to-copper direct bonding strength

Shadow is an advanced direct metallization for HDI and flex type constructions which allows for plating of complex through holes in a simple and easy to control process.

Shadow Sales Sheet (EN)

PCB, Rigid Flex, Any Layer HDI. Shadow Does It All.

The numbers don’t lie. Shadow is the number one direct metallization solution for advanced through hole and via plating sold today. Whether you’re plating single or stacked vias, low or high aspect ratio through holes, Shadow does it cleaner, faster, and more reliably than any other metallization process.

Shadow is capable of plating materials that electroless copper and other direct metallizations cannot. Complex designs such as any layer HDI, complex blind vias and high aspect ratio through holes are no match for Shadow technology. Advanced substrates such as high frequency PCB materials, PTFE and flex boards are fully compatible with the Shadow process.

Meet the Experts

With over 100+ years of experience working with Direct Metallization, our dedicated team is here to answer your questions.

For any inquiries regarding MacDermid Alpha Direct Metallization, send us an email at AskOurDMExperts@macdermidalpha.com.