Product Overview

The Affinity ENEPIG process is a simple to operate process providing uniform nickel, palladium, gold deposits with high reliability for soldering and wire bonding applications at the lowest cost of ownership.

The proprietary palladium and gold baths offer chemical stability during intermittent operation without wasteful plate out on equipment. The palladium deposit is consistently uniform and paired with hybrid gold deposition delivers a corrosion free, highly solderable and bondable surface . The Affinity ENEPIG system is one of the most desirable universal final finish systems on the market today.

Product Features

- Delivers superior wire bond performance

- Excellent solderability for leaded and lead-free applications

- Provides wide thickness plating range

- Extremely stable bath chemistry, simplified bath control

- Corrosion Free Deposition

The Affinity ENEPIG process is an easy to run process that plates a uniform nickel, palladium, gold coating with high reliability for soldering and wire bonding operations at the lowest cost of ownership compared to similar systems.

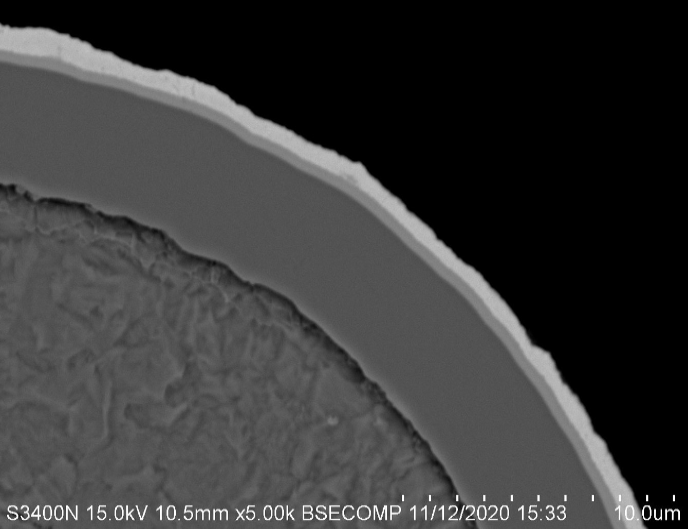

Corrosion Observations Reduced to Zero

Hybrid gold deposition allows improved gold thickness capability without total reliance on galvanic displacement of the EN deposit. The resultant AFFINITY ENEPIG surface is corrosion free thus eliminating reliability concerns associated with traditional systems.

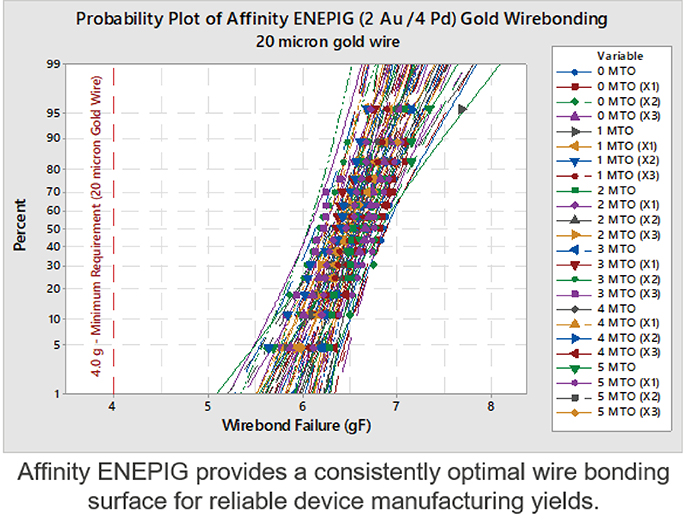

Wire Bonding Performance Over A Wide Operating Window

A gold surface that is receptive to highly sensitive wire bonding operations is a highly important design feature for IC substrate designs. The Affinity ENEPIG process plates a nickel-palladium-gold surface that consistently provides the foundation for strong gold wire bond strength. The performance of the wire bonding does not degrade with bath life and remains stable after the coating has been subjected to multiple assembly reflow thermal exposures.

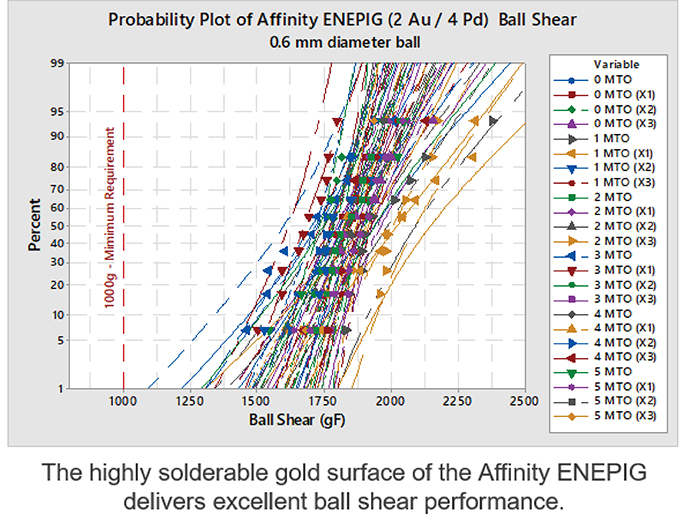

Excellent Ball Shear Solderability Performance

Solderability operations are typically conducted on the IO pads of the IC substrate for advanced chip packaging designs. The small scale and large number of pads per unit involved require a final finish that has extraordinary solderability to ensure trouble-free assembly and device lifetimes. The highly solderable nickel-palladium-gold coating of Affinity ENEPIG provides consistent ball shear performance over long chemical bath life under multiple reflow operations. The process delivers these excellent solderability characteristics while also adhering to IPC4556 thickness specifications for the coating.