Product Overview

Manufacturers of advanced printed circuit boards struggle to overcome the challenge of core layer and other through hole filling for thermal and structural applications. Fabricators can achieve improved thermal conductivity over paste filling, skip resource intensive planarization steps, and achieve excellent reliability with the solid copper filling provided by the Systek THF Series, allowing for greater design freedom.

Product Features

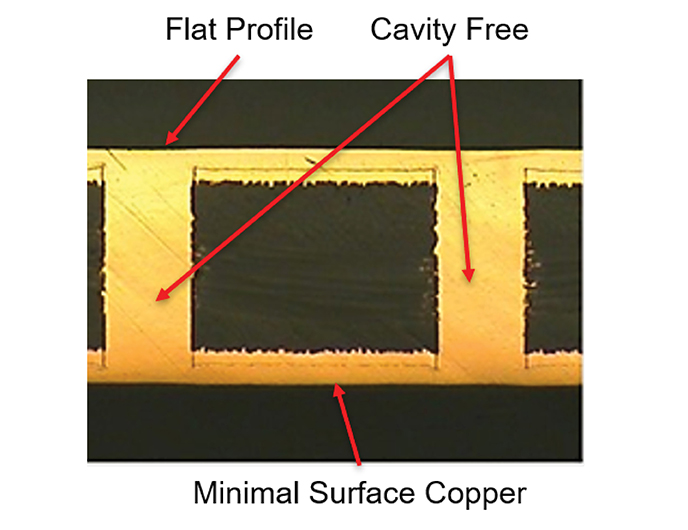

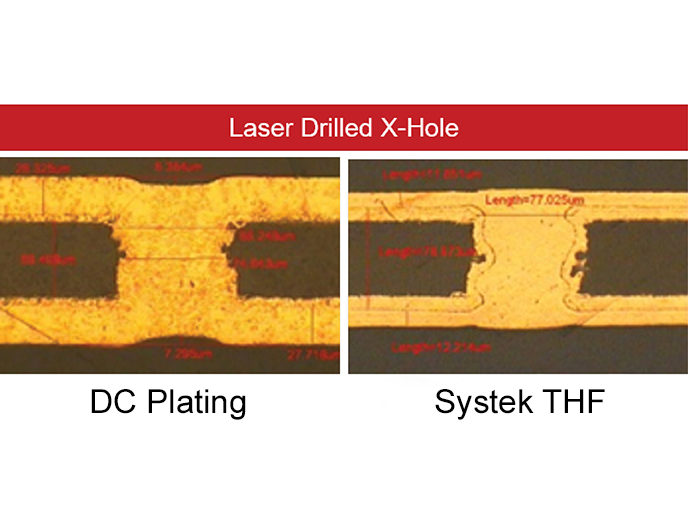

- Unparalleled cavity free filling of through holes vs DC copper

- Flat filling for subsequent stack build ups

- Minimization of surface copper for HDI applications

- Improved thermal conductivity

- Drastically reduced plating times

- Elimination of planarization processes

Compared to existing filling processes, the Systek THF Series through hole filling process eliminates hole voiding, reduces cycle time, and provides solid copper through hole structures. The process minimizes surface copper buildup and fills through holes in a wide range of board thicknesses and hole diameters in a fraction of the time with less wasted metal than DC processes.

Systek THF Series Sales Sheet (EN)

Advanced Cu Electroplating Process For Any Layer Via Fill Applications With Thin Surface Copper Technical Publication APEX 2018 (EN)

Copper Pillar Plating Systems High Speed - Low Heat Technical Publication SMTAI 2017 (EN)

Copper Pillar Plating Systems Technical Publication SMTAI 2018 (EN)

Copper Plating Process for Filling Micro Vias and Through via Holes with Minimum Surface Deposition Technical Publication EIPC 2013 (EN)

Effect of Chemical and Processing Parameters on Hole Filling Characteristics of Copper Electroplating Technical Publication APEX 2012 (EN)

Electroplated Copper Filling Of Through Holes Influence Of Hole Geometry Technical Publication SMTAI 2016 (EN)

Electroplated Copper Filling of Through Holes on Varying Substrate Thickness Technical Publication IMPACT 2014 (EN)

Electroplating Processes For IC Substrates - Embedded Trace Plate, Via Fill And Through Hole Fill Technical Publication IMPACT 2018 (EN)

Innovative Electroplating Processes for IC Substrates - Via Fill, Through Hole Fill, and Embedded Trench Fill Technical Publication PCB007 2019 (EN)

Single Step Metallization Process for the Filling of Through Hole with Copper Technical Publication IMPACT 2020 (EN)

Single Step Metallization Process for the Filling of Through Hole with Copper Technical Publication SMTAi 2020 (EN)

Systek IC Substrate Brochure (EN)

Compared to existing filling processes, the Systek THF Series through hole filling process eliminates hole voiding, reduces cycle time, and provides solid copper through hole structures. The process minimizes surface copper buildup and fills through holes in a wide range of board thicknesses and hole diameters in a fraction of the time with less wasted metal than DC processes.

In comparison to competitive technologies that require multiple copper plating steps, Systek THF Series achieves complete filling by reducing the number of solutions to maintain and eliminating unnecessary metal interfaces for enhanced reliability.