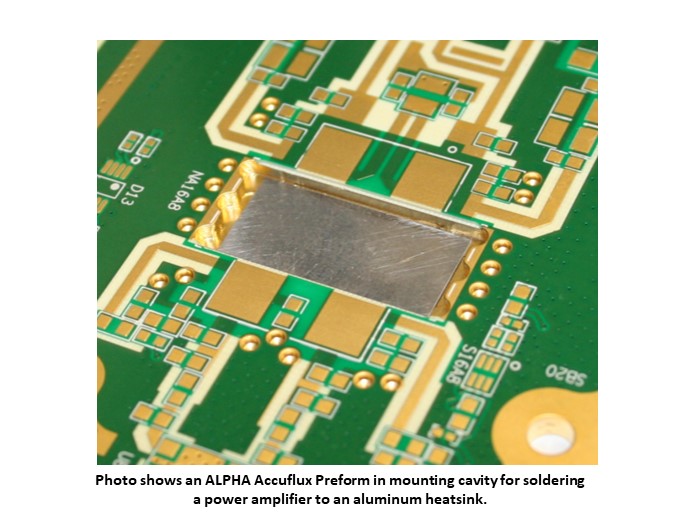

Product Overview

Low voiding is a significant advantage that provides high manufacturing yields, superior in-service performance and a high level of product reliability. The ALPHA AccuFlux Preform manufacturing process is unique in that it guarantees that each preform will have the same amount of flux, within a tightly controlled range. Another key consideration is the low flux weight percent required to yield good solder wetting, the result of which is lower levels of residual flux in no clean applications.

Product Features

- Various preform sizes and thicknesses available

- Fast placement using standard pick and place equipment

- Low-tack flux formulation

- Preforms available in all standard solder paste alloys

- 7” and 13” standard EIA-481 tape and reel packaging format

Technical Bulletins

ALPHA AccuFlux Preform Technical Bulletin English

Product Brochures

Technical Paper

Void Reduction Strategy for Bottom Termination Components (BTC) Using Flux Coated Preforms Paper English

Benefits of ALPHA Accuflux Preforms

- Extremely low voids in solder joints to manage effective heat dissipation and RF performance

- Enhanced process stability and predictable reliability through repeatable void distribution

- Enhanced electrochemical reliability by producing extremely low flux residues