Product Overview

ALPHA OM-565 HRL3 low temperature solder paste is designed to mitigate warpage induced defects in temperature sensitive chip-scale packages. The solder paste enables peak reflow temperatures of 175 °C and superior wettability to minimize post reflow defects such as Non-Wet-Open (NWO) and Head-in-Pillow (HIP).

The ALPHA OM-565 chemistry enhances electrochemical performance over existing low melt point solders and provides excellent compatibility when used in combination with alternative ALPHA solutions for contact rework applications.

Product Features

- Compatibility with HRL3 alloy for enhanced thermomechanical and drop shock reliability.

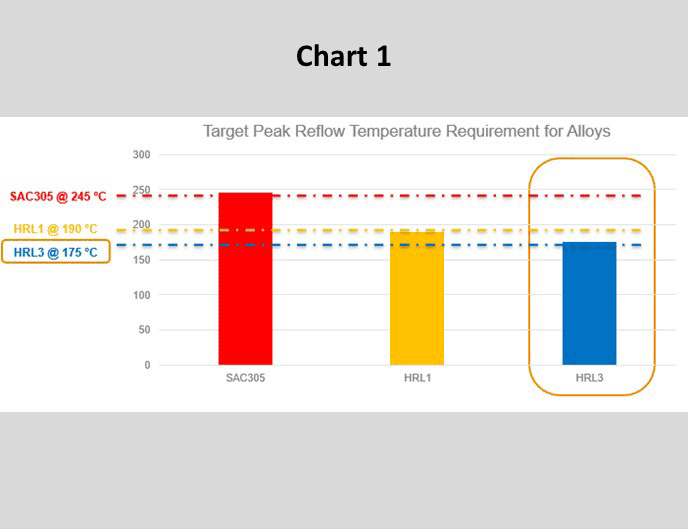

- The HRL3 alloy enables peak reflow temperature of 175 °C to mitigate warpage induced defects.

- Low melt point reflow improves energy efficiency and reduces energy costs in the assembly process.

- Superior HiP/NWO performance.

- Compatibility with contact rework applications.

- 8-hour stencil life in ambient and elevated conditions.

Minimizes Warpage Induced Defects to Maximize Assembly Yield

Next generation devices require a larger footprint and thinner form factor design that deliver superior processing power over existing technologies. These next generation packages create challenges for assembly at traditional SMT reflow temperatures. ALPHA OM-565 HRL3 enables a reduction in peak reflow down to 175 °C to mitigate common warpage induced defects such as HiP and NWO to improve assembly yields.

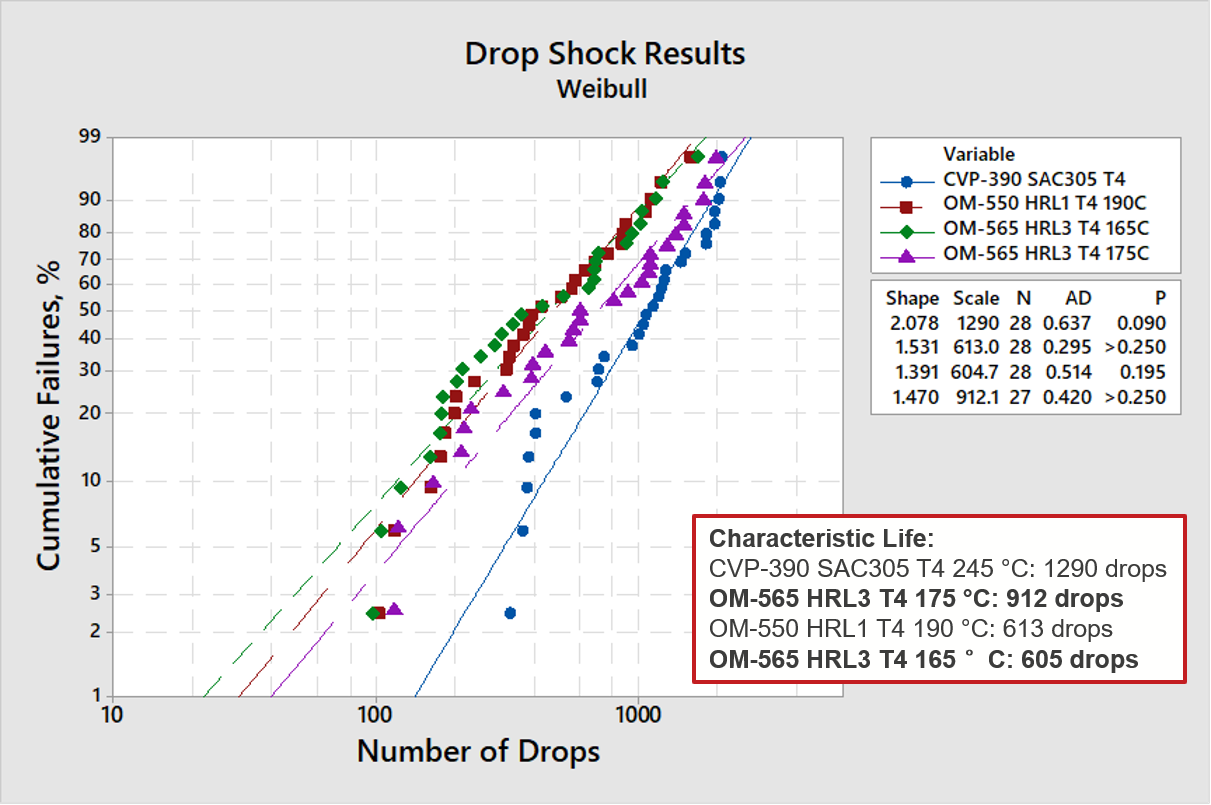

HRL3 Alloy Improves Reliability Over Existing Low Temperature Solutions

ALPHA OM-565 HRL3 microalloying additions continue to enhance the mechanical reliability over existing best-in-class low temperature solutions. The resulting ductility of the HRL3 alloy and superior wettability of the ALPHA OM-565 chemistry further advances the drop shock performance of low melt point alloys.

Enhances the Environmental Sustainability of the Assembly Process

The HRL3 alloy offers a significant reduction in peak reflow temperature over existing SAC reflow conditions. The ability to reliably solder at 175 °C peak temperatures will increase the efficiency of existing assembly processes while lowering the manufacturers net impact on its surrounding environment.