Product Overview

ALPHA HiTech AD13-9910B is a one-component, ultra-low temperature cure epoxy system. It can be cured at temperatures as low as 60°C, enabling excellent adhesion strength and a reduction in the defect rate on very temperature sensitive parts and substrates.

ALPHA HiTech AD13-9910B is suitable for plastic parts or substrates that are very sensitive to high temperature exposure and exhibits excellent adhesion strength on Stainless Steel (SUS), Nickel, PCBs and Liquid Cystal Polymer (LCP).

Product Features

- Excellent dispensing performance – jetting [< 35°C at nozzle], time/pressure or auger

- Fast cure at very low temperatures

- Meets market reliability requirements including adhesion strength at high humidity/high temperatures

- Halogen-Free

- Complies with RoHS Directive 2015/863/EU

Ultra Low Temperature Curing Capability

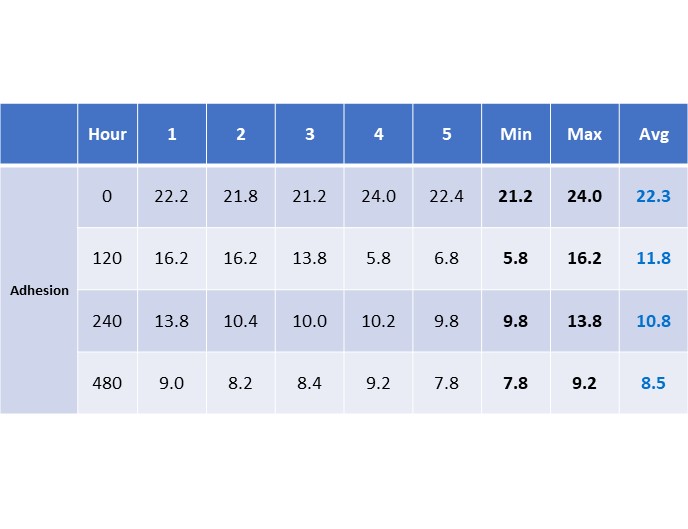

ALPHA HiTech AD13-9910B has the ability to cure at temperatures as low as 60°C, providing excellent adhesion strength. After prolonged exposure to high temperature/high humidity (85°C/85%), the cured material still exhibits good adhesion strength. This helps to lower defect level on parts very sensitive to higher temperatures.