Product Overview

We provide innovative chemistries to aid in all aspects of printed circuit formation. Our goal is to aid fabricators to increase yields and reduce total cost of ownership in all aspects by providing high-quality, unique solutions. From dry film adhesion to final finish, we deliver. Our process chemistries form the bedrock of the printed circuit board (PCB) manufacturing process and include resist strippers, developers, innerlayer cleaners, dry film resists, and more.

Product Features

- Industry standard resist strippers, developers, innerlayer cleaners, and dry film resists.

- UltraStrip resist strippers for stripping fully aqueous photoresist.

- CoreClean innerlayer cleaning for removal of zincate, chromate, and silane pretreatments.

- PHOTEC brand dry film photoresists with high first pass yields and fine line resolution.

Our goal is to aid fabricators to increase yields and reduce their total cost of ownership by providing high quality, unique solutions. From dry film adhesion to the final finish step, we deliver the right solution.

Totalimage Brochure (EN)

Resist Strippers

The UltraStrip product line represents our most advanced, high-performance photoresist strippers. The UltraStrip RS-215 Resist Stripping System is designed to strip fully-aqueous dry film photoresists. Its unique blend of components promotes a high strip rate, easily filterable particles, and complete removal of dry film residues and adhesion promoters. UltraStrip RS-215 contains no caustic, glycol ethers or any other solvents, so it will not attack copper, tin, or tin-lead.

Photoresist Developers

The MacDermid Enthone photoresist developers are highly concentrated aqueous photoresist developer solutions, making feed-and-bleed control of the developer solution simple and consistent. Developer 45 Plus contains effective descaling and anti-scumming additives plus the ease of handling a pure liquid concentrate. The Developer 40 contains no suspended particles, reducing clogging and wear of the apparatus compared to solid carbonate. Neither contain EDTA or other complexors.

Innerlayer Cleaner

CoreClean was developed as a flexible surface preparation process for innerlayers prior to the application of either dry film or liquid resist. It includes cleaners capable of removing the most tenacious chromate, zincate, and silane anti-tarnish treatments, and can be used with or without a microetch and/or antitarnish depending on the needs of the user.

Develop-Etch-Strip (DES)

The UltraStrip product line represents our most advanced, high-performance photoresist strippers. UltraStrip formulas are optimized for the market-leading dry films, uniquely formulated to provide a high strip rate, easily filterable particles, and complete removal of dry film residues and adhesion promoters, even under over-plated circuits. Our Eliminator products, used in outerlayer tin stripping, are recognized for their abilities to uniformly remove tin with minimal attack on copper traces.

Copper Thinning

CircuEtch 100 is a high-speed, peroxide-sulfuric copper etch suitable for a variety of printed circuit manufacturing applications. It is the product of choice in the controlled reduction of copper thickness for CO2 LDD, LED, and PCB applications. The copper surface is “polished” during etch, with reduced surface roughness, even at high etch rates. A wide range of copper etch rates can be achieved by adjusting the operating conditions.

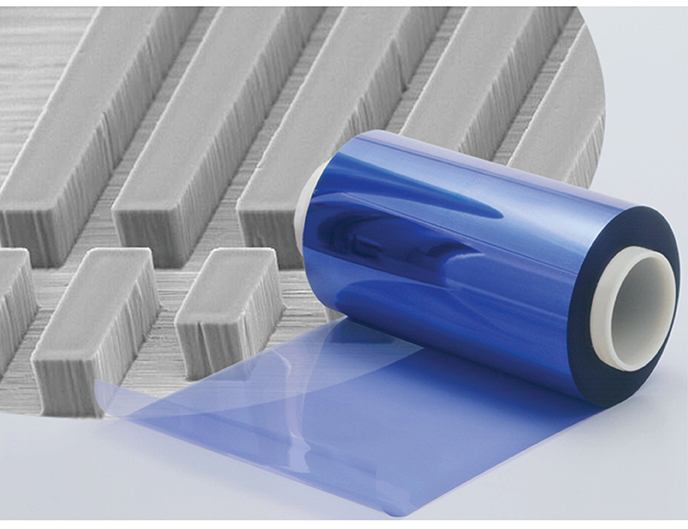

Dry Film Resists

PHOTEC dry film photoresists provide high reliability for a diverse range of process conditions. The PHOTEC series offers superb conformity on all commonly used substrates and ensuring the highest PCB yields at the lowest possible cost. PHOTEC dry film photoresists are manufactured by RESONAC, exclusively marketed and distributed by MacDermid Alpha throughout Europe, and supported by MacDermid Alpha’s European technology team. PHOTEC dry film photoresist rolls are custom slit at certified facilities.

The PHOTEC series dry film photoresists provide highest first-pass yields, due to high-resolution-enabling fine line structures, good adhesion, tenting properties, and excellent substrate conformance. PHOTEC series dry film resists are easy to strip with controlled particle sizes, thus significantly reducing clogged equipment and nozzles, and have no or very low sensitivity for sludge formation. Their extremely strong tenting capabilities can be used to overcome obstacles encountered by challenging layouts.

Various PHOTEC dry film photoresists are available for a variety of applications, including:

|

PHOTEC |

Series For |

|---|---|

|

PHOTEC H series |

Conventional and DI exposure, R-R applications, Electrolytic Nickel / Gold and metal etching. |

|

PHOTEC HM series |

Thick resist layers metal etching |

|

PHOTEC RD series |

Fine line DI applications |

|

PHOTEC RY series |

PKG boards and ultra-fine line. |

|

PHOTEC H-W series |

Electroless Ni/Au applications |

PHOTEC dry film photoresists are manufactured by Showa Denko Materials (Japan) and exclusively marketed and distributed by us throughout Europe. Backed by unmatched technical support, PHOTEC dry film rolls are custom slit at our certified facilities.

Available in Europe only.